As of August 26, 2025, all trainings will be hosted on Brightspace.

Training

Hunter College is committed to providing a safe and healthy workplace. The success of the college's environmental compliance and occupational health and safety efforts depends on all of us working together and accepting personal responsibility for our safety and the safety of those with whom we work. Training is an integral tool to achieving this success. Below is a list of scheduled training sessions, and the descriptions of each type of training.

Training FAQs

We have developed two training guides that outline the training required for each job category to help you determine what training you require.

- For all Public Safety, ICIT, or Facilities training, please see the Training Matrix, or check for Brightspace training under your department/trades.

- For all laboratory or research personnel training, please see Brightspace training under your department.

-

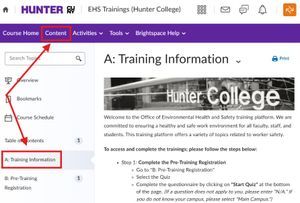

- Navigate to the EHS Training Course on Brightspace.

- Log in using your CUNY credentials (formatted as First.Last##@login.cuny.edu).

- Once logged in, you'll be directed to the training course. Click on “Open Course” to access the trainings.

-

- Note: If you are not pre-enrolled in the course, you may submit a request to be enrolled. Refer to the FAQ “How to Request Access” for more information.

-

- Inside the course, select “Content” from the Navigation Bar and follow the instructions under “A: Training Information” to complete your training and receive your certificates." Please make sure to watch the entire video, including the completion message at the end.

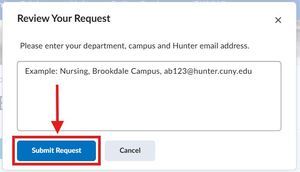

If you are NOT pre-enrolled in the course, you may submit a request to be enrolled:

- Click on “Request Approval”

- Enter your department, specify your campus, and provide your Hunter email address. Then, click “Submit Request” to proceed with your

approval request.

- Once your request is approved, you will receive a confirmation email. You can then move forward with completing the EHS trainings.

If you cannot view the trainings after accessing the course, it is likely that you did not complete the Pre-Training Registration. Please revisit the course and ensure that the Pre-Training Registration form is submitted correctly.

The pre-training registration form must be completed to ensure your training is properly recorded. Without completing this form, you will not gain access to the trainings.

To complete the Pre-Training Registration:

- Access the EHS Training Course on Brightspace.

- Navigate to “B: Pre-Training Registration.” Select the Quiz by clicking the blue link

- Complete the questionnaire by clicking “Start Quiz” at the bottom of the page.

- Answer all 5 questions.

- If a question does not apply to you, enter “N/A.”

- If you're unsure of your campus, select “Main Campus.”

- Ensure to “Submit Quiz” to finalize your registration."

Please refer to the Regulatory Training Guide for the comprehensive list of trainings required for your role.

All trainings available on Brightspace are organized by Department/Trade:

- Navigate to your designated 'Department folder.'

- Complete all the training listed within your department folder that is related to your tasks; for example, only chemistry labs that have biosafety cabinets require BSL training.

- Ensure you watch each training video in its entirety, including the completion message at the end.

Please contact the Office of Environmental Health and Safety at ehs@hunter.cuny.edu if you have any questions.

All courses listed below are available on Brightspace unless otherwise noted. If you need to attend a training session that isn't available on Brightspace, please contact the Office of Environmental Health and Safety at ehs@hunter.cuny.edu.

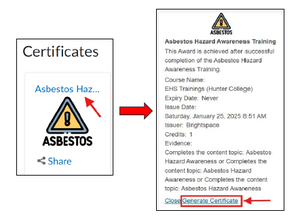

To access your Completion Awards:

- Navigate to 'Awards' on the navigation bar.

- Click on the name of the 'Certificate'; a pop-up window will appear.

- Select 'Generate Certificate' to print or save a copy of your certificate.

Note: You will receive a completion certificate for every EHS training you successfully complete.

Training Courses A - C

Required for all maintenance and custodial staff, and workers who work in a building containing ACBM. Asbestos is a naturally occurring mineral known for its excellent heat- and fire-resistant properties. Throughout the 20th century, asbestos was commonly used in building materials, pipe coatings, flooring, paint, texturing, and many other applications. Unfortunately, inhaling asbestos fibers can cause asbestosis, a chronic and often fatal lung disease.

Fortunately, U.S. manufacturing began phasing out asbestos in the 1970s. However, there are still many buildings, homes, and commercial facilities that contain Asbestos-Containing Building Materials (ACBMs).

This course will provide workers with an overview of asbestos safety, including:

- How asbestos exposure can occur.

- The negative health effects of asbestos exposure.

- Common safety practices to avoid exposure.

This course is presented in English and Spanish.

The National Institute for Occupational Safety and Health (NIOSH) estimates that back injuries account for nearly 20% of all workplace injuries and cost the nation an estimated $20 to $50 billion annually. This course aims to educate learners about the major causes of workplace back injuries and how to prevent them. Employees who complete this course will learn to:

- Identify hazards that lead to back injuries.

- Understand the three major types of hazard controls.

This course is intended for general industry employees who, during their regular work duties, are required to lift and carry materials. It is presented in English and Spanish.

Labs designed for work with biological materials must have safe work practices in place to protect personnel, the facility, and the surrounding community. These work practices fall into four biosafety levels, or BSLs, that are ranked from 1 to 4.

This course will address the general protections and requirements for BSL-2 environments.

Required annually for anyone at risk of occupational exposure to blood or potentially infectious materials.

The Occupational Safety and Health Administration (OSHA) recognizes that many employees come into contact with human blood or other potentially infectious materials during their daily duties, thus exposing them to occupational hazards. OSHA’s Bloodborne Pathogen Standard serves as the foundation for implementing policies and practices to minimize workers' risk of exposure to bloodborne pathogens (BBPs), specifically the Hepatitis B virus (HBV), the Hepatitis C virus (HCV), and the Human Immunodeficiency Virus (HIV).

This course will educate employees about the hazards of bloodborne pathogens in the workplace and the basic controls required under OSHA’s Bloodborne Pathogen Standard. Participants will learn to:

- Identify major bloodborne diseases and their symptoms.

- Understand how pathogens are transmitted.

- Apply the basics of exposure prevention and incident response and cleanup.

This awareness-level course is designed for all workers who may be exposed to blood or other potentially infectious materials (OPIM) during the performance of their regular job duties.

The course is available in English, Spanish, German, Portuguese, and Mandarin.

Required if work that is being done, meets chemical hygiene standards or is advised to take this training.

A lot of important scientific research and development is done in laboratories, and many people depend on their work. However, lab workers can face several hazards, particularly chemical hazards. The Occupational Safety and Health Administration (OSHA) requires labs to create a formalized chemical hygiene plan to help protect employees from these hazards.

Learners who successfully complete this course will be able to:

- Recognize the purpose and components of a chemical hygiene plan.

- Identify their responsibilities in the continued implementation of such a plan.

This course is designed for all workers, students, or other personnel who will work in a laboratory.

Required for all employees who work with or around hazardous chemicals.

The Occupational Safety and Health Administration (OSHA) estimates thirty-two million employees work with at least one chemical hazard every day. OSHA requires labs to create a formalized chemical hygiene plan to help protect employees from these hazards.

Learners who successfully complete this course will be able to:

- Recognize the purpose and components of a chemical hygiene plan.

- Identify their responsibilities in the continued implementation of such a plan.

This course is presented in English and Spanish.

Required for people who work outdoors or in cold indoor environments, such as walk-in freezers, are frequently subject to cold, wet working conditions.

These environments can take a heavy toll on workers’ bodies and pose significant health hazards. Workers in these conditions must be prepared to manage these challenges.

Learners who successfully complete this course will be able to:

- Identify factors that contribute to cold stress.

- Recognize signs and symptoms of cold stress.

- Implement controls to help prevent cold stress.

This course is presented in English and Spanish.

Compressed gas cylinders are designed to hold gases under extremely high pressures in a relatively small container. While convenient, they present significant hazards.

This course will help employees learn to:

- Identify the hazards of compressed gases and compressed gas cylinders.

- Understand the labeling and storage requirements for cylinders.

- Implement safe work practices.

This course is presented in English, Spanish, German, Portuguese, and Mandarin.

Confined spaces are some of the most hazardous work environments. This course will teach employees about the hazards and safety precautions associated with confined spaces, with a strong emphasis on OSHA safety requirements.

Employees will learn to:

- Identify confined spaces.

- Recognize the hazards of confined spaces.

- Implement methods to control those hazards.

- Understand regulations regarding permit-required confined spaces.

This course is intended for general industry employees who are required to work in or around areas defined by OSHA as confined spaces. It is designed to help employers meet OSHA’s standards on permit-required confined spaces.

This course is presented in English and Spanish.

COVID-19 is a respiratory disease caused by a virus known as severe acute respiratory syndrome (SARS-CoV-2). While some people can work from home or work alone, many others must still work in close proximity to others. This course is designed to help all workers understand SARS-CoV-2 and how to prevent its spread in both work and home environments.

Upon completing this course, learners should be able to:

- Identify general preventive measures for virus transmission.

- Implement strategies to prevent the spread of disease in the workplace.

Training Courses D - K

Falling is consistently one of the most common causes of workplace fatalities. Falls from as little as 4 to 6 feet can cause serious injuries, sometimes even death. Given the variety of work environments, there are numerous types of fall hazards.

This course will teach employees the importance and practice of consistent fall protection.

Employees will learn to:

- Recognize fall hazards.

- Identify fall protection methods.

- Implement various safe work practices.

This course is presented in English, Spanish, German, Portuguese, and Mandarin.

Tools are such a common part of our lives that it's easy to forget they can pose potential hazards to our safety. This course will teach employees the importance of hand and power tool safety and how to achieve it.

Employees who successfully complete this course will learn:

- The common hazards associated with different types of hand and power tools, including electrical, pneumatic, hydraulic, and abrasive-wheel tools.

- How to minimize or eliminate these hazards.

This course is intended for general industry employees who, as part of their regular work duties, are required to use or work around hand and power tools. It can also assist employers in meeting regulations outlined in OSHA's regulations on hand and power tools.

This course is presented in English and Spanish.

Required for all personnel who work with hazardous materials or conduct hazardous operations:

- During a new employee’s initial orientation.

- When major aspects of a job change, or new materials or hazards are introduced to the workplace.

Many employees in various industries work with hazardous chemicals. The Occupational Safety and Health Administration (OSHA) has an Occupational Chemical Database that currently lists more than 800 hazardous chemicals used in U.S. workplaces. Many of these chemicals can cause injury or death if workers don’t take the right precautions.

Employees who successfully complete this course should be able to:

- Recognize the purpose and requirements of a hazard communication (HAZCOM) program.

- Identify chemical hazards and their controls in their workplace.

- Identify sources of information for workplace chemical hazards.

- Understand requirements for medical recordkeeping.

This course is designed for employees who need initial or refresher HAZCOM training. It is presented in English and Spanish.

The Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) have stringent requirements for hazardous waste storage, handling, and transportation. Improper disposal of waste could result in hefty fines and potential environmental damage.

This course is designed to teach employees about the Resource Conservation and Recovery Act (RCRA) and their responsibilities when dealing with hazardous waste at work.

Employees will learn to:

- Identify and describe the basics of federal hazardous waste regulation.

- Define hazardous waste.

- Understand the different generator status categories.

This course is intended for employees who, as part of their regular work duties, are required to work with or around hazardous waste. It can assist employers in meeting OSHA and EPA requirements on hazardous waste.

This course is presented in English and Spanish.

Working in high heat can cause numerous health issues, particularly for workers who are not acclimated to such conditions. This course will teach employees about the hazards of working in high heat and how to minimize or eliminate those hazards.

Employees who successfully complete this course will learn to:

- Identify the hazardous health effects of high heat.

- Implement methods to prevent those health effects.

- Respond if a co-worker exhibits symptoms of heat stress, such as heat fatigue, heat rash, heat cramps, heat exhaustion, and heat stroke.

This course is intended for employees who, during their regular work duties, are exposed to high-temperature conditions for significant periods of time. It is presented in English and Spanish.

Hot work includes any tasks that produce fire or sparks, such as welding, flame cutting, soldering, and brazing. While these activities are essential, they also pose significant health hazards to workers. Training, safe practices, and hazard controls are crucial to keep workers safe.

This course will help employees to:

- Identify types of hot work and their associated hazards.

- Understand employee roles and responsibilities for hot work.

- Receive information on specific hazards related to hot work, additional associated hazards, and hazard controls for performing hot work.

This course assists employers in meeting the requirements of OSHA Standard 29 CFR 1910.252 (General Requirements) and 254 (Arc Welding and Cutting). It is intended for employees who perform hot work, including welding, brazing, and torch cutting, as part of their regular duties.

In addition to this course, employers might also provide training on Compressed Gas Safety, Fire Safety, and Portable Fire Extinguishers. While this course addresses OSHA training requirements, there may be a site-specific training component that must be fulfilled by the employer.

This course is available in English and Spanish.

Ergonomics is the process of reducing worker injury through effective workplace design, such as decreasing the amount of bending or reaching for items or using equipment to reduce strain on the human body. This course will teach employees how to apply ergonomics in industrial settings to minimize injuries.

Employees who successfully complete this course will learn to:

- Identify ergonomic risk factors.

- Recognize potential injuries.

- Implement methods to minimize or eliminate ergonomic hazards.

This course is designed to provide general industry employees with the skills to identify and improve ergonomic conditions for themselves in the workplace, and it assists employers with compliance with OSHA’s General Duty Clause.

This course is presented in English and Spanish.

Physical hazards are an inherent part of every job, though some jobs might present more serious risks than others. Job hazard analysis can help employees identify hazards in their workplaces and protect themselves from them.

Learners who successfully complete this course will demonstrate knowledge of:

- The basic concepts and procedures of job hazard analysis.

- The need for effective job hazard analysis.

- How to prepare for a job hazard analysis.

- The process of identifying workplace hazards and how to correct them.

This course is intended for general industry employees and safety officers who are interested in improving the safety of work practices either in their own work processes or within their companies. It is presented in English and Spanish.

Training Courses L - Z

Required every three years for anyone who works in a laboratory with hazardous materials or operations.

Many laboratories generate hazardous waste. The Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) have stringent requirements for generators of hazardous waste. Failure to comply can result in hefty fines and pose risks to workers and the environment.

This course provides an overview of the Resource Conservation and Recovery Act (RCRA) and its application to laboratory waste, particularly in educational and research settings. Upon completing this course, learners should be able to:

- Identify different types of waste defined by RCRA and their characteristics.

- Understand the accumulation, storage, and recordkeeping requirements imposed by RCRA.

This course is designed for all employees and students working in a laboratory that generates hazardous waste.

Required every three years for anyone who works in a laboratory with hazardous materials or operations.

A lot of important scientific research and development is conducted in laboratories. Industries such as healthcare, pharmaceuticals, and oil and gas rely on lab results to create processes and products, and to save lives. However, laboratory workers face various hazards.

This course will teach lab workers to identify common physical, chemical, and biological laboratory hazards, and related safe work practices. It is designed for all laboratory workers operating in laboratories and research facilities.

Ladders are one of the most common and simple tools used on the job. It’s easy to forget that they can also be extremely dangerous. Each year in the United States, ladder-related accidents result in approximately 300 deaths and 130,000 injuries requiring emergency medical attention.

This course will assist learners in:

- Identifying different types of ladders.

- Understanding general safe practices for working on ladders.

- Recognizing the importance of ladder inspection, setup, and location.

- Implementing best practices for safe ladder use.

This course is presented in English, Spanish, German, Portuguese, and Mandarin.

Lockout/tagout is a system designed to keep workers safe while servicing or repairing equipment by making it physically impossible for that equipment to run or move. This course will teach employees how lockout/tagout programs work and the different roles workers must play to ensure their success.

Employees who successfully complete this course will learn to:

- Identify the importance of proper lockout/tagout procedures.

- Recognize which workers are authorized to perform these procedures.

- Understand the lock and tag systems used for lockout/tagout.

- Apply the special provisions of lockout/tagout programs.

This course is intended for employees who, during their regular work duties, are required to perform lockout/tagout procedures, as well as for those who work on equipment subject to regular maintenance or repair requiring lockout/tagout.

This course is presented in English, Spanish, German, Portuguese, and Mandarin.

Moving machine parts have the potential to cause severe workplace injuries, such as crushed fingers or hands, amputations, burns, or blindness. Any machine part, function, or process that may cause injury must be safeguarded.

Employees who successfully complete this course will learn to:

- Define machine guarding.

- Locate fundamental machine areas.

- Identify machine hazards.

- Understand the types of machine guards.

- Recognize the types of machine devices.

This course is intended for employees who, during their regular work duties, are required to work with or around machines equipped with guarded machinery. It can also assist employers in meeting the provisions of OSHA’s Machinery and Machine Guarding standards.

Mobile elevating work platforms (MEWPs), including aerial and scissor lifts, are crucial for safely reaching high places in various work environments. However, improper use can lead to serious injuries. This course will teach employees about the safe operation of these platforms.

Employees who successfully complete this course will learn to:

- Identify different types of mobile elevating work platforms.

- Understand the hazards associated with MEWPs.

- Follow safe work practices for operating aerial and scissor lifts.

- Implement inspection and maintenance procedures for MEWPs.

This course is intended for employees who, as part of their regular duties, use or work around aerial and scissor lifts. It assists employers in meeting safety regulations and ensuring a safe work environment.

This course is presented in many different languages.

Learners who successfully complete this course will display the ability to recognize standard pallet jack types, controls and functions, procedures for pallet jack inspection and safe operation, and common hazards associated with pallet jack operation. This course includes information about both manual and powered pallet jacks, and is designed to assist pallet jack operators and their employers to complete the formal training (classroom) portion of OSHA’s required training for operators of Class III powered industrial trucks.

This course is presented in English and Spanish.

Personal protective equipment, or PPE, has been around throughout history in various forms. Even everyday clothing is a form of PPE, but many jobs and workplaces have unique hazards that require additional protection, such as gloves, boots, eye protection, and more.

This course will teach employees to:

- Identify the need for PPE.

- Define the concept of a hazard assessment.

- Consider factors when choosing PPE.

- Understand the different types of PPE used to protect all parts of the body.

This course is intended for general-industry employees who, during their regular work duties, are required to use personal protective equipment. It is presented in English, Spanish, German, Portuguese, and Mandarin.

Many work environments contain airborne particles that can be hazardous if inhaled. These include airborne viruses, harmful chemical fumes, and certain types of dust particles, all of which can cause injury or illness if breathed in. When the air becomes unsafe to breathe, employees may need respiratory protection.

This course equips learners with knowledge of basic respiratory protection and its application in the workplace.

Participants will learn about:

- potential inhalation hazards

- various types of respirators and their uses

- how to fit test a respirator mask, and

- the care and maintenance of respirators.

Designed for general industry employees who need to wear respiratory protection during their regular duties, this course helps employers comply with OSHA's Respiratory Protection Standard. While it covers OSHA training requirements, additional site-specific training, hands-on practice, and health testing may be required by employers.

The course is available in English, Spanish, and German.

Scaffolding is a very versatile and useful tool for the construction or repair of buildings. It can be easily assembled and disassembled, and can be built tall or wide, depending on the building’s shape. However, using scaffolding requires care and knowledge.

This course will teach employees the basics of staying safe while working on scaffolds.

Employees will learn:

- The definition of a scaffold.

- The potential hazards of working on a scaffold, such as falls, electrocution, and scaffold collapse.

- Major hazard control methods.

This course is intended for employees who are required to perform work on scaffolds. It can help employers comply with OSHA’s safety requirements for scaffolding.

An important job for any municipality is providing clean water and disposing of wastewater for its citizens. This essential task carries certain hazards, primarily from exposure to bacteria and other infectious agents contained in sewage and wastewater.

Workers who successfully complete this course will learn about the major hazards associated with sewage, wastewater, and water line maintenance.

Learners will be able to:

- Identify the major physical and exposure hazards of sewage, wastewater, and water line maintenance.

- Implement preventative measures to mitigate these hazards.

This course is intended for municipal sewage and water line maintenance workers and managers.

Many employees work with hazardous chemicals every day, and with that comes the risk of spills. Some spills can be cleaned up by workers on-site, while others may require emergency responders. Even simple spills of hazardous chemicals can harm human health and the environment, so employees need to be aware of the hazards and how to clean them up safely.

Learners who successfully complete this course will be able to:

- Recognize sources of spill response information.

- Identify considerations when dealing with small spills.

- Implement procedures and best practices for handling small spills.

This course is presented in English and Spanish.

The Environmental Protection Agency (EPA) states that a single gallon of oil can contaminate up to one million gallons of water. To safeguard waterways, the EPA mandates that all non-transportation facilities storing significant quantities of oil must develop and adhere to a spill prevention, control, and countermeasure (SPCC) plan.

This course aims to equip learners with the ability to identify the fundamental components of an SPCC plan, recognize spill prevention strategies, and understand spill control measures and countermeasures.

The course is available in both English and Spanish.

Consumers and businesses discard thousands of tons of material every day. When items like batteries, fluorescent light bulbs, and unused pesticides are dumped in landfills with regular trash, they create hazards to the environment and to public health. To help reduce the amount of hazardous and toxic waste in landfills and the environment, the EPA has established the Universal Waste Regulation.

Learners who successfully complete this course will be able to:

- Recognize different types of universal waste.

- Understand proper handling and disposal procedures for universal waste.

This course is intended for employees in all industries who are required to handle or dispose of materials classified as universal waste by OSHA.

This course equips learners with knowledge of basic respiratory protection and its application in the workplace. Participants will learn about potential inhalation hazards, various types of respirators and their uses, how to fit test a respirator mask, and the care and maintenance of respirators.

Designed for general industry employees who need to wear respiratory protection during their regular duties, this course helps employers comply with OSHA's Respiratory Protection Standard. While it covers OSHA training requirements, additional site-specific training, hands-on practice, and health testing may be required by employers.

The course is available in English, Spanish, and German.